Description

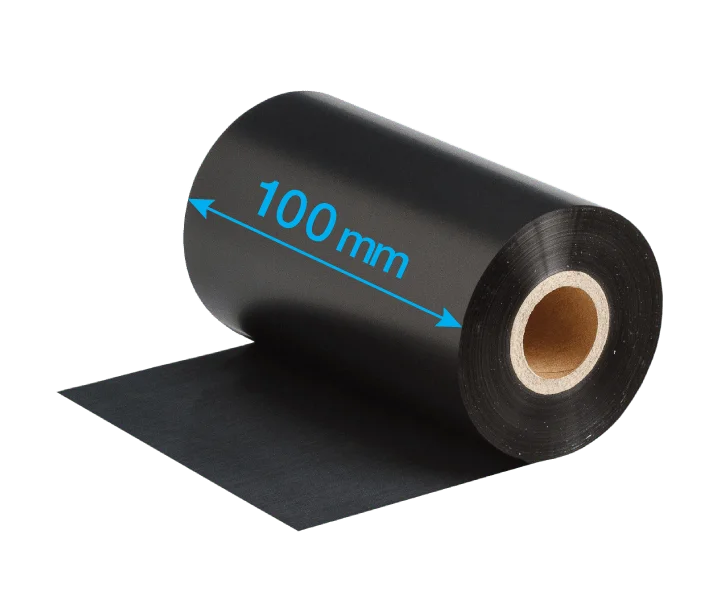

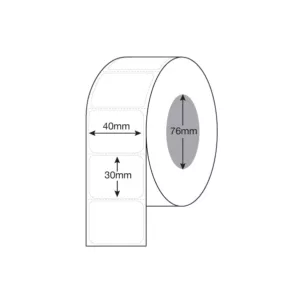

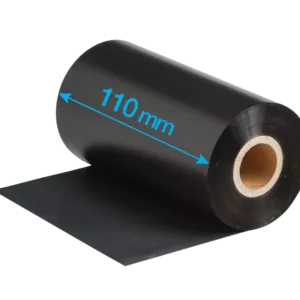

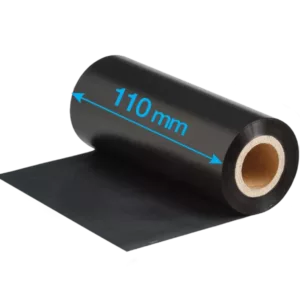

The most common thermal ribbon used in Australia is “WAX RESIN”As the name suggests, Wax Resin Thermal Ribbon grade is a mixture of wax and resin. The resin in a thermal ribbon is what gives it better scratch and smudge resistance, so it is best for logistic labels or food packaging applications. Within the grade wax resin, there are several variations which have different resin content levels. The more resin in a ribbon product, the more expensive & durable it will be. Depending on how much resistance you require you may be able to use a lower cost alternative which is often as good as the premium brands like Ricoh. We recommend this grade for matt transfer & gloss paper labels, as well as most synthetics they will not be exposed to harsh conditions. Additionally, ensure your ribbon is wider than your label material (including backing). This prevents paper stocks from damaging your printhead. Ink-In or In-Out?Ribbons are manufactured with the ink on the inside or the outside of the roll. This is because different Thermal Printers have different winding paths for thermal ribbons. Another commonly used term is Carbon Side In (CSI) and Carbon Side Out (CSO). Check your printer to select the option you need, or contact us for assistance. |  |